Introduction

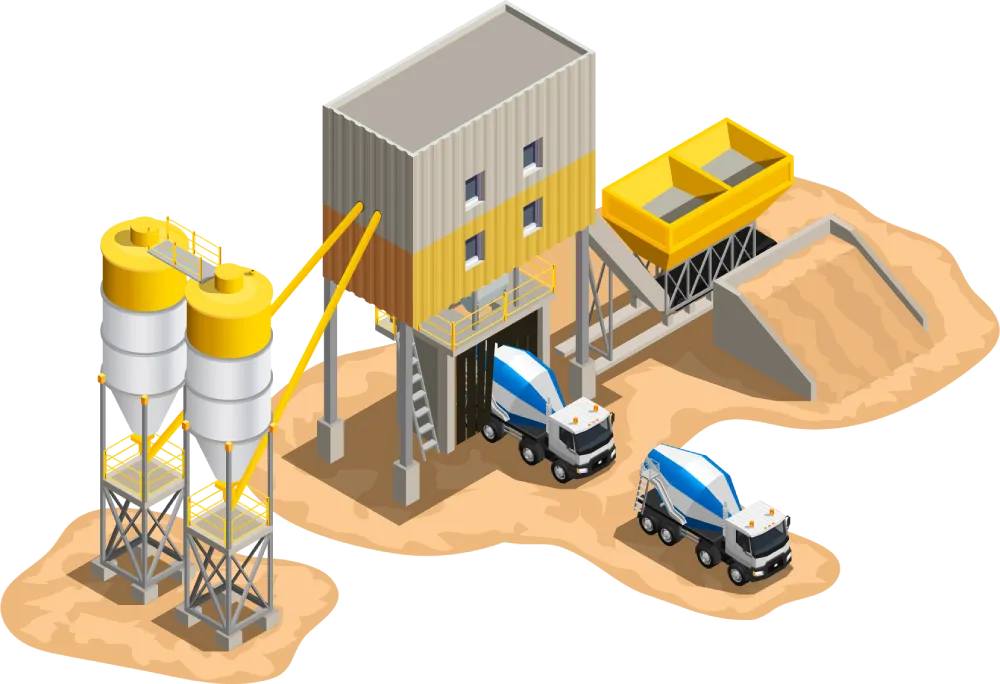

Turnkey plant erection and startup of concrete batching plants involves a contractor delivering a fully operational plant, handling design, supply, installation, civil and electrical works, and initial operator training. Key steps include securing permits, site preparation, assembling equipment, utility hookups, safety certifications, and commissioning with plant trials. The turnkey approach provides a complete solution, offering convenience and expertise from a single contractor for efficient plant operation.

Key Components of a Turnkey Project

Design & Engineering: Includes plant layout, structural, equipment design, and civil and electrical works design.

Equipment Supply: Sourcing and providing all necessary batching plant machinery and related components.

Civil & Electrical Works: Designing and executing the civil foundations and electrical infrastructure for the plant.

Erection & Installation: The physical assembly and construction of the batching plant on-site.

Permits & Compliance: Obtaining the necessary permits for construction, environmental compliance, and safety certifications.

Commissioning: The process of starting up the plant, including comprehensive trials to ensure it meets operational specifications.

Training: Providing professional operator training to ensure smooth and efficient plant operation