Rubber chutes are flexible discharge channels used in concrete batching plants to guide freshly mixed concrete from one point to another—most commonly from the mixer outlet to the transit mixer, skip, or conveyor.

Rubber chutes are flexible discharge components installed in concrete batching plants to guide freshly mixed concrete from the mixer, weigh batcher, skip hoist, or conveyor discharge point into transit mixers or receiving hoppers.

Application

- Mixer discharge outlet

- Weigh batcher outlet

- Skip hoist discharge

- Belt conveyor discharge point

Common types of rubber chutes

- Straight rubber chutes – simple vertical or inclined flow

- Tapered chutes – control concrete flow rate

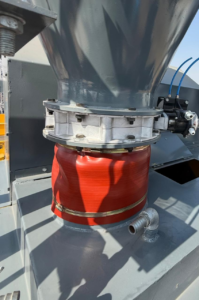

- Flanged rubber chutes – bolted to mixer or hopper outlets

- Replaceable liner chutes – rubber lining inside steel housing

Material

- Silicon

- Natural Glossy Flexible Tomato Red

- Natural Flexible Mat Finish

- EPDM Tomato Red

- Heavy-duty natural or synthetic rubber

- Often reinforced with fabric or steel layers

- Designed to resist abrasion, impact, moisture, and cement chemicals

Reinforcement

- Fabric-reinforced (standard applications)

- Steel-reinforced (heavy-duty / high-capacity plants)

Uses

Compared to rigid steel chutes, rubber chutes offer several advantages:

- Flexibility

Easily bends to align with truck mixers of different heights

Absorbs vibration and movement during discharge

- Reduced wear & tear

Concrete causes less abrasion on rubber than metal

Helps extend service life of discharge components

- Smooth concrete flow

Minimizes segregation of aggregates

Reduces spillage and dust generation

- Noise reduction

Much quieter than steel chutes during discharge

Maintenance & care

- Regularly check for cuts, cracks, or thinning

- Ensure proper clamping or bolting

- Clean buildup to avoid hardening of concrete inside the chute

- Inspect regularly for tears, hardening, or liner wear, as degradation can cause blockages or contamination. Replace sections every 6-12 months based on usage intensity, and clean post-shift to prevent buildup. In high-volume plants, urethane-lined rubber extends life by 2-3 times over standard rubber.

Key benefits in concrete production

- Prevents material loss and site mess

- Improves plant cleanliness

- Enhances operator safety

- Reduces maintenance downtime

Typical specifications (vary by plant)

- Thickness: 2–12 mm

- Diameter: Based on mixer outlet size

- Temperature resistance: Suitable for fresh concrete

- Abrasion resistance: High (cement + aggregates)

- Length: Sufficient to ensure smooth discharge into transit mixer & avoid excessive length to prevent material buildup

- Mounting Type: Flanged or clamped connection to mixer outlet

Note: Secure bolting to prevent leakage or detachment

- Operating Conditions: Designed for fresh concrete temperature & Suitable for continuous batching plant operation