Overview

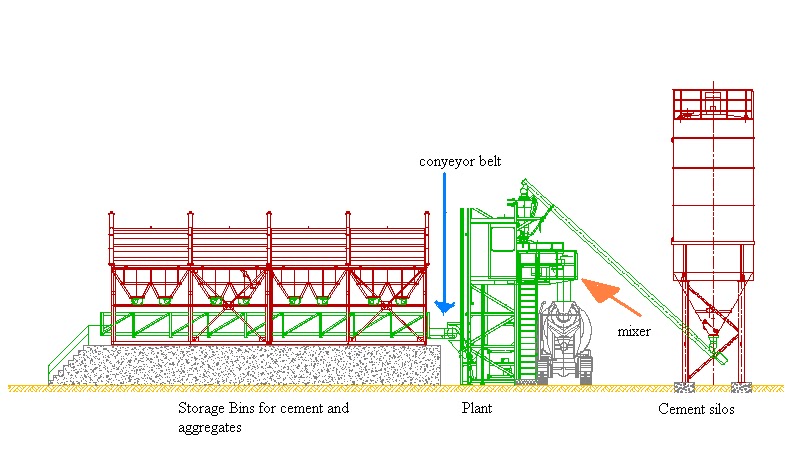

In the Ready Mix Concrete (RMC) plant industry, “Upgrades & Modernization” refers to the process of improving existing plant infrastructure, equipment, systems, and practices to enhance efficiency, productivity, safety, sustainability, and product quality by focusing on automation, digitalization, efficiency, and sustainability through advanced control systems, high-performance mixers, and intelligent logistics. This is critical for companies to remain competitive, meet regulatory standards, and adapt to evolving technologies and customer demands.

These advancements reduce costs and labor, increase productivity and quality, improve safety, and ensure compliance with regulations.

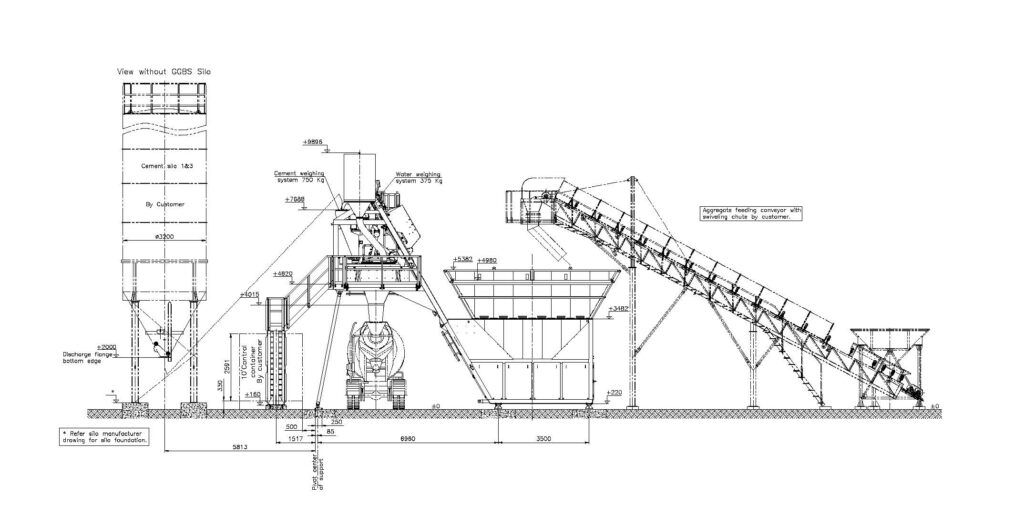

Key areas for improvement include upgrading mixers, batching and control systems, optimizing raw material handling, enhancing delivery logistics, and integrating digital tools for real-time monitoring and data analysis.

Key Areas of Upgrades and Modernization

Automation and Digitalization: Implementing advanced control systems (like SCADA) with features such as real-time data monitoring, improved automation, and digital reporting enhances efficiency, productivity, and product consistency.

High-Performance Equipment: Upgrading to high-performance mixers with advanced designs can significantly improve mixing efficiency, reduce energy consumption, and increase overall plant throughput.

Improved Control Systems: Modernizing the batching and control systems with the latest technology provides better accuracy, consistency, and the ability to generate reports and alerts, ensuring adherence to standards and requirements.

Optimized Raw Material Handling: Automating raw material handling with systems like stacker reclaimers and using more efficient crushing and drying equipment can improve blending precision and reduce energy consumption.

Enhanced Logistics and Delivery: Modernizing the plant layout, vehicle routes, and parking areas improves the efficiency and safety of the delivery process, preventing congestion and ensuring orderly operations.

Sustainability and Compliance: Upgrades allow plants to comply with evolving environmental regulations, reduce energy consumption, and adopt eco-friendly practices, contributing to a more sustainable industry.

Safety Improvements: Reducing manual intervention through automation and implementing better control systems significantly reduces the risk of accidents, improving worker safety.

Data Management and IoT Integration: Use of cloud-based systems, remote monitoring, and predictive maintenance via IoT sensors to minimize downtime, better planning, and performance analytics.

Energy Efficiency & Sustainability: Installation of solar panels, energy-efficient motors, or variable frequency drives (VFDs) to lower operating costs and reduced carbon footprint.